Office

53 Lester St, Wallington NJ 07057

Warehouse

1019 Underwood Rd, Olypant PA 18447

Phone

(917) 445-7671

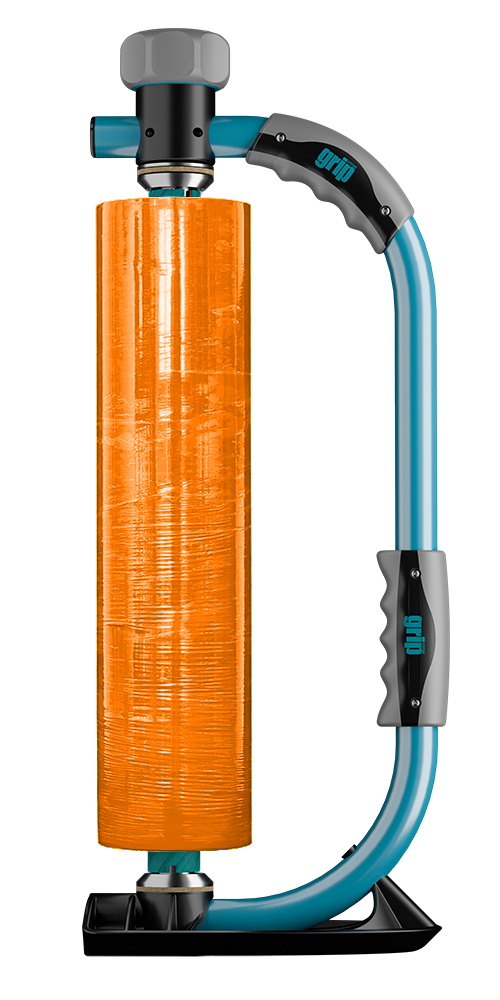

GRIP Film

INNOVATIVE PALLET WRAP TECHNOLOGY

HIGHEST YIELD, LOWEST THICKNESS

40% REDUCTION IN TIME, WASTE AND COST

High-yield, lightweight, sustainable solutions. Converting standard stretch material via a secondary process, film is pre-stretched to its maximum elasticity, converting a high yield film to a reduced-thickness performance solution with improved efficiencies and environmental savings.

Grip Film is used globally to reduce clients’ carbon footprints, with a reduced consumption of up to 50% material due to increased yield per roll. The reduced thickness equates to much less plastic needed per wrap, resulting in not only cost savings but huge waste savings.

Increase your holding force and pallet stability with Grip Film. The film memory creates higher hold force ensuring load stability and increased security. The oscillated edges of the film increase the strength of the wrap and prevent breakage and damage to dropped rolls.

Pre-stretched films perform extremely well in all climates. Grip Film is safe to use in ambient, chilled and cold store environments. The opaque white film effectively reflects the sun, protecting goods from harsh sun rays and heat damage.

Thanks to the secondary process in manufacture, our films have an improved application. They’re easier, lighter and faster to unwind, control and apply. Guarantee a consistent wrap with Grip Film, due to the pre-stretched quality removing elasticity and creating a more uniform stretch.

Key Features of Grip film

What makes Grip Film so unique and how will it save you 40% across your operations?

Climate Resistance

Carbon Footprint Reduction

High Strength and Puncture Resistance

Guaranteed Load Stability

blown grip film

Elite

Light Duty Film

Clear

Pre-stretched

Premium

Heavy Duty Film

Clear

Pre-stretched Film

Superior

Medium Duty Film

8 Tints available

Pre-stretched Film

ECO FILM

CAST FILM

OPAQUE FILM

Premium Eco

Heavy Duty Film

Pre-Stretched, Clear

Contains 30% Recycled Content

Elite Eco

Light Duty Film

Pre-Stretched, Clear

Contains 30% Recycled Content

Carbon

Light Duty Film

Pre-Stretched, Clear

Available with 30% Recycled Content

Classic

Heavy Duty

Pre-Stretched, Clear

Available with 30% Recycled Content

Robust White

Heavy Duty

Opaque Film

Available with 30% Recycled Content

Robust Black

Heavy Duty

Opaque Film

Available with 30% Recycled Content

Office

53 Lester St, Wallington NJ 07057

Warehouse

1019 Underwood Rd, Olypant PA 18447

Phone

(917) 445-7671